Choosing the Right Medical Plastic Injection Molding Company: A Comprehensive Guide

Introduction: Medical plastic injection molding plays a crucial role in the manufacturing of medical devices and equipment. When it comes to producing high-quality and precise medical products, selecting the right injection molding company is paramount. This article will guide you through the key considerations, benefits, and steps involved in the medical plastic injection molding process, along with industry trends and advancements.

Key Considerations when Selecting a Medical Plastic Injection Molding Company:

- Experience and Expertise: Opt for a company with a proven track record in medical device manufacturing. Their experience ensures they understand the unique requirements and complexities involved in producing medical products.

- Compliance with Regulations: Verify that the company adheres to industry regulations and holds relevant certifications such as ISO 13485, ensuring compliance with quality management systems for medical devices.

- Quality Control Measures: Look for a company with stringent quality control procedures and certifications like ISO 9001. This ensures that every product meets the highest standards of quality and safety.

- Production Capabilities: Assess the company’s production capabilities and capacity to ensure they can handle your project requirements efficiently and deliver within the specified timelines.

- Design and Engineering Support: Choose a company that offers comprehensive design and engineering support. Their expertise will help optimize your product design for manufacturing, resulting in improved efficiency and cost-effectiveness.

Benefits of Partnering with a Specialized Medical Plastic Injection Molding Company:

- Customization and Product Development Support: A specialized company can provide tailored solutions to meet your unique product requirements. They offer expertise in material selection, design optimization, and prototyping, facilitating the development of innovative medical devices.

- Cost-effectiveness and Efficiency: By leveraging their expertise and advanced manufacturing techniques, a specialized company can streamline the production process, reducing costs and minimizing waste.

- Enhanced Product Quality and Precision: Specialized medical plastic injection molding companies employ advanced technologies and quality control measures, ensuring the production of high-quality, precise, and consistent medical products.

- Streamlined Supply Chain Management: Partnering with a specialized company allows for better coordination and integration within the supply chain, resulting in improved inventory management and reduced lead times.

Case Studies of Successful Medical Plastic Injection Molding Projects:

- Example 1: XYZ Company partnered with a specialized medical plastic injection molding company to develop a complex medical device. The company’s expertise in design optimization and material selection resulted in a cost-effective and efficient production process, meeting stringent quality standards.

- Example 2: ABC Corporation collaborated with a specialized injection molding company to manufacture high-volume medical consumables. The company’s production capabilities and streamlined supply chain management ensured timely delivery and consistent product quality.

Steps Involved in the Medical Plastic Injection Molding Process:

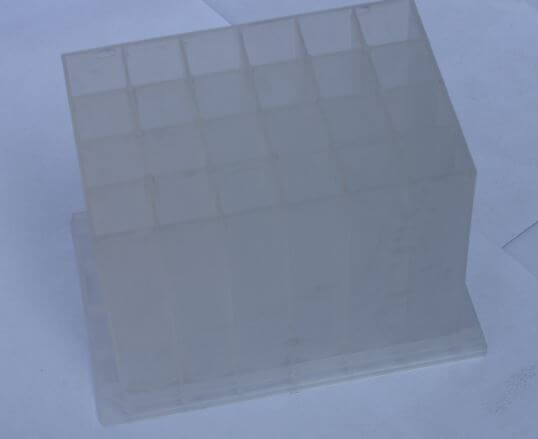

- Mold Design and Fabrication: The process begins with the design and fabrication of molds tailored to the specific medical product. Advanced software and precision machining techniques are utilized to create molds that meet the desired specifications.

- Material Selection and Preparation: The appropriate medical-grade plastic material is chosen based on factors such as biocompatibility, durability, and sterilization requirements. The material is then prepared for the injection molding process.

- Injection Molding and Production: The prepared material is injected into the mold under high pressure and temperature. This process allows for the creation of intricate shapes and features of the medical product.

- Quality Control and Inspection: Rigorous quality control measures are implemented throughout the production process. Comprehensive inspections and tests ensure that each product meets the required standards of quality, functionality, and safety.

Industry Trends and Advancements in Medical Plastic Injection Molding:

- Introduction of Bioresorbable Materials: The industry is witnessing the emergence of bioresorbable materials that can be safely absorbed by the body. These materials offer new possibilities for developing temporary medical implants and reducing the need for additional surgeries.

- Integration of Automation and Robotics: Automation and robotics are being increasingly integrated into the injection molding process. This results in improved efficiency, reduced labor costs, and enhanced precision, ensuring consistent product quality.

- 3D Printing and Additive Manufacturing: The utilization of 3D printing and additive manufacturing techniques is gaining momentum in medical device production. These technologies enable rapid prototyping, customization, and the creation of complex geometries, revolutionizing the manufacturing process.

At Sincere Tech, a leading injection mold manufacturer in China, we recognize the significant role custom injection molding plays in achieving manufacturing excellence. With our extensive expertise in the field, we are proud to offer high-quality custom injection molding services that adhere to the most stringent industry standards.

Our team comprises skilled professionals who are dedicated to delivering exceptional results tailored to your specific needs. Equipped with state-of-the-art equipment and driven by a commitment to innovation, we ensure a seamless and efficient manufacturing process from start to finish.

Right from the initial design phase, we prioritize meticulous attention to detail to guarantee that every product meets your exact specifications. Our experienced engineers work closely with you, offering valuable insights and recommendations to optimize the design for injection molding. This collaborative approach leads to cost-effective solutions without compromising on quality.

We harness the unique properties of plastic materials to create products that boast not only a superior surface finish but also tight tolerances. This not only results in reduced waste rate costs but also contributes to improved energy efficiency and enhances the overall user experience.

No matter your industry or application, our custom injection molding capabilities cater to a wide range of needs. Whether you require consumer goods, automotive components, electrical enclosures, medical devices, or industrial parts, we have the expertise and resources to meet your requirements.

Partner with Sincere Tech China mold maker for your custom injection molding needs and experience the benefits of our exceptional manufacturing capabilities, attention to detail, and commitment to delivering top-quality products that exceed your expectations.

If you have a plastic mold project that is looking for mould suppliers to support you, contact us to get price now.

Conclusion: Selecting the right medical plastic injection molding company is crucial for the successful production of high-quality and precise medical devices. By considering factors such as experience, compliance, quality control, production capabilities, and design support, you can ensure a seamless partnership. Collaborating with a specialized company offers numerous benefits, including customization, cost-effectiveness, enhanced quality, and streamlined supply chain management. Stay informed about industry trends and advancements to leverage the latest technologies and materials in your medical device manufacturing journey.